Sticking to safety and quality

Safety certification at the world’s highest level

OEKO-TEX® standard 100 certification obtained

Nippon Dom obtained OEKO-TEX® standard 100 certification, the highest safety certification level in the world, in 2000, which was the first in Japan in the label industry.

- Printed Label Certification

- Woven Label Certification

- Recycle Product Certification

OEKO-TEX® standard 100 is intended to eliminate effects and damage to humans by harmful materials and is applied to raw materials, semiprocessed goods, and final products in all processing stages of fabrics. It is a unified testing and certification system worldwide. OEKO-TEX® labels guarantee the safety and security of products and naturally serve as a reliable indicator to consumers, while also helping to smooth transactions between various industries domestically and overseas.

- Broken needle management

- Sewing needles, metals, and other dangerous items are not included. When a needle breaks during the work process, work is immediately interrupted and the needle removed. The needle is replaced only after it is confirmed that the recovered needle has been restored. Furthermore, needles are managed with a dedicated file and use history can be traced.

- Checks by inspection meters

-

Safe labels are supplied through 2 or 3 layers of inspection meters in the manufacturing process.

-

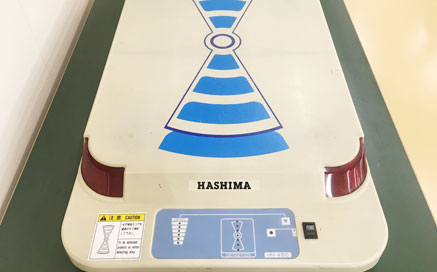

- Conveyor inspection meters

-

- Desktop inspection meters

-

The scissors and cutters used in the company are all given management codes and checked after work.