Sticking to safety and quality

An exhaustive management system based on handmade quality has been established.

It is not an exaggeration to say that quality is everything for a brand label.

This includes visible quality, including beauty, color, and design, as well as invisible quality, including fastness in laundering, etc.

Furthermore, in recent years, in addition to these two, safety has come under demand as a third measure of quality.

Chemicals and other materials that cause adverse effects on human bodies are not used. This is also an indispensable requirement for brand labels.

As such, we established an internal Quality Control Committee in order to increase customer satisfaction. We carry out and follow arrangements for quality control throughout all processes of creation to maintain quality and make improvements from the ordering stage to delivery.

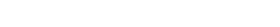

Nippon Dom quality support devices

- Ammonia deodorant test

- Oven

- Fading test equipment

- Scott-type crease-flex abrasion tester

- Gakushin-type rubbing tester

- Bench-top type temperature and humidity chamber

- Washer / dryer

- Accelerotor Type Abrasion Tester

- Inspection meter

MSDS is obtained from the raw material manufacturer, quality confirmed through performance evaluation testing(physical properties and fastness), formaldehyde content is confirmed, and use of fluorescent brighteners is confirmed.

Management of formaldehyde content

Formaldehyde is controlled by law.

“Law for the control of household products containing harmful substances” October 12, 1973, Law No. 112

<Specific management measures for formaldehyde content>

- All materials in the printed label and woven label material sample book have been checked for formaldehyde.

- Those that are not checked for formaldehyde cannot have manufacturing orders issued.

【Details of formaldehyde regulations for textile products】

| Hazardous material | Formaldehyde |

|---|---|

| Applications | Resining agent, preservative(for glue) |

| Applicable housewares |

|

| Standards |

(1)undetectable (absorbance 0.05 or lower) (2)75ppm or lower (per 1g sample, 75mg or lower) |

| Toxicity | Membrane irritation Skin allergy |

All lots are washed/tumble dried 10 times repeatedly and only the labels that passed are shipped.

JIS L0217, 103 washing equivalent 10 times repeated(drying is by tumbling)

Other than printed labels, laser cut products and supersonic wave cut products are also repeatedly washed 10 times and checked for presence of fraying.

All defective printed label and woven label products that arise in the production process are shredded at Nippon Dom and subjected to exhaustive controls to ensure that no brand labels are unlawfully carried out and used.

Also, after they are shredded, labels are re-processed by a vendor and finally reused as solid fuel to make efficient use of this valuable resource and care for the environment.

- Shredder

- step01

- Defective products that arise in the production process are shredded

- step02

- Shredded labels

- step03

- Re-processed solid fuel after shredding(used for industrial purposes)